Have you ever wondered how beekeepers actually get the honey out of the hive and into the jar? Highland beekeeper, Dominic Fitzsimmons, is on hand to tell us how he handles this sticky situation. Watch the slideshow below to learn more about how Highland honey is harvested:

We first have to get the honey from the hives, where the thousands of bees are busy storing it away in the mistaken belief that they will be eating it over the winter - don't worry, we give them something else to eat. Firstly, we have to get the bees out of the honey super - the special box we put on top of the hive during the nectar flow, the time of the year when local plants are in bloom. In the image above you can see just how many bees we have to move.

We first have to get the honey from the hives, where the thousands of bees are busy storing it away in the mistaken belief that they will be eating it over the winter - don't worry, we give them something else to eat. Firstly, we have to get the bees out of the honey super - the special box we put on top of the hive during the nectar flow, the time of the year when local plants are in bloom. In the image above you can see just how many bees we have to move. We have to gently encourage the bees to quietly move down into the lower levels of the hive, all the while thinking it was their idea to leave. We do this by using a fume board, the top side of which is covered in black plastic to absorb heat from the sun and transfer it to its felt underside, upon which we spray an almond-based oil which these ladies find particularly unpleasant.

We have to gently encourage the bees to quietly move down into the lower levels of the hive, all the while thinking it was their idea to leave. We do this by using a fume board, the top side of which is covered in black plastic to absorb heat from the sun and transfer it to its felt underside, upon which we spray an almond-based oil which these ladies find particularly unpleasant. The fume board is installed above the honey super, driving the bees down into the rest of the hive. Any hangers on are given a gentle shove with a leaf-blower - battery operated, of course, as we don't want any nasty fumes tainting the lovely honey they have labored all summer to collect.

The fume board is installed above the honey super, driving the bees down into the rest of the hive. Any hangers on are given a gentle shove with a leaf-blower - battery operated, of course, as we don't want any nasty fumes tainting the lovely honey they have labored all summer to collect. Each honey super contains nine frames, upon which the bees have built honeycomb into which they have stored honey. We only take frames that have been completely capped in beeswax; any cells the bees have left uncapped contain honey that has not reached the optimum moisture content – good honey is 15.5-17% water, much higher and it could ferment.

Each honey super contains nine frames, upon which the bees have built honeycomb into which they have stored honey. We only take frames that have been completely capped in beeswax; any cells the bees have left uncapped contain honey that has not reached the optimum moisture content – good honey is 15.5-17% water, much higher and it could ferment. As there are nine – not the standard ten – frames in a honey super, the bees build into the extra space, leaving the wax cap above the level of the wooden frame. This allows the frame to be placed on an uncapping machine and pushed across a pair of steam-heated blades, which make short work of the top layer of wax. The wax cappings which are removed and fall into the tank are made of high-quality wax and are used to make cosmetics.

As there are nine – not the standard ten – frames in a honey super, the bees build into the extra space, leaving the wax cap above the level of the wooden frame. This allows the frame to be placed on an uncapping machine and pushed across a pair of steam-heated blades, which make short work of the top layer of wax. The wax cappings which are removed and fall into the tank are made of high-quality wax and are used to make cosmetics. Much of the equipment used to harvest honey has been refined over time as beekeepers find new methods to make the process more efficient. The honey extractor is a great example of how the ancient art of beekeeping has advanced over the millennia. We place the honey-filled uncapped frames into the motor driven extractor, which then spins them rapidly using centrifugal force to fling the honey out of the honeycomb.

Much of the equipment used to harvest honey has been refined over time as beekeepers find new methods to make the process more efficient. The honey extractor is a great example of how the ancient art of beekeeping has advanced over the millennia. We place the honey-filled uncapped frames into the motor driven extractor, which then spins them rapidly using centrifugal force to fling the honey out of the honeycomb. The honey hits the walls of the extractor tanks and drips down the side and drains out of a faucet into a double sieve which filters any residual wax particles.

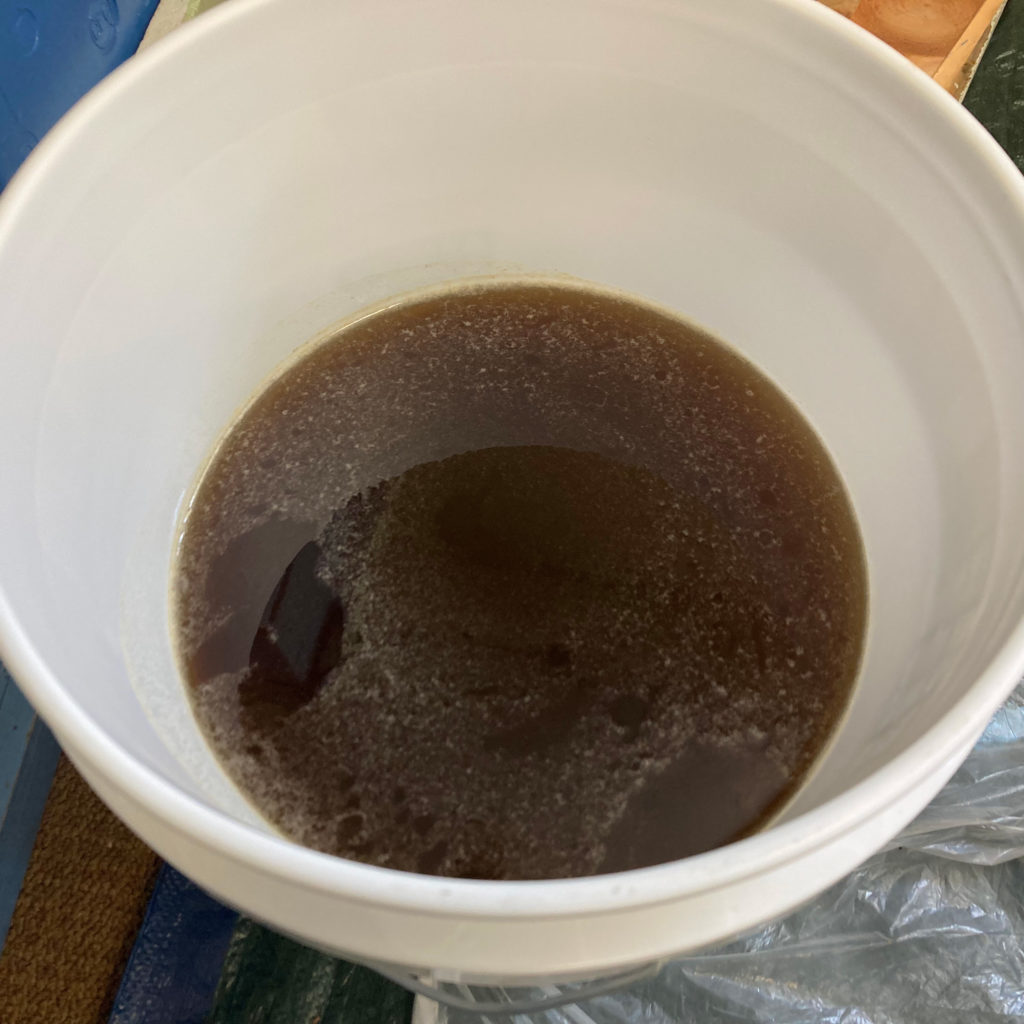

The honey hits the walls of the extractor tanks and drips down the side and drains out of a faucet into a double sieve which filters any residual wax particles. The filtered honey is collected in a food-safe 5-gallon bucket. These buckets have a tap installed to facilitate bottling into individual jars.

The filtered honey is collected in a food-safe 5-gallon bucket. These buckets have a tap installed to facilitate bottling into individual jars. With the extraction process complete, honey is transferred to individual jars. As a thank you for supported the Highland Bee Project, donors are the recipient of a jar of honey.

With the extraction process complete, honey is transferred to individual jars. As a thank you for supported the Highland Bee Project, donors are the recipient of a jar of honey.

To learn more about the Highland Bee Project visit https://highland.org/bee-project/.

*Images courtesy of Dominic Fitzsimmons and Evan O’Neill.